Perkhidmatan dan Proses Binaan Kotak

Pembangunan, Pengeluaran dan Pengurusan Kehidupan Produk Dipermudahkan

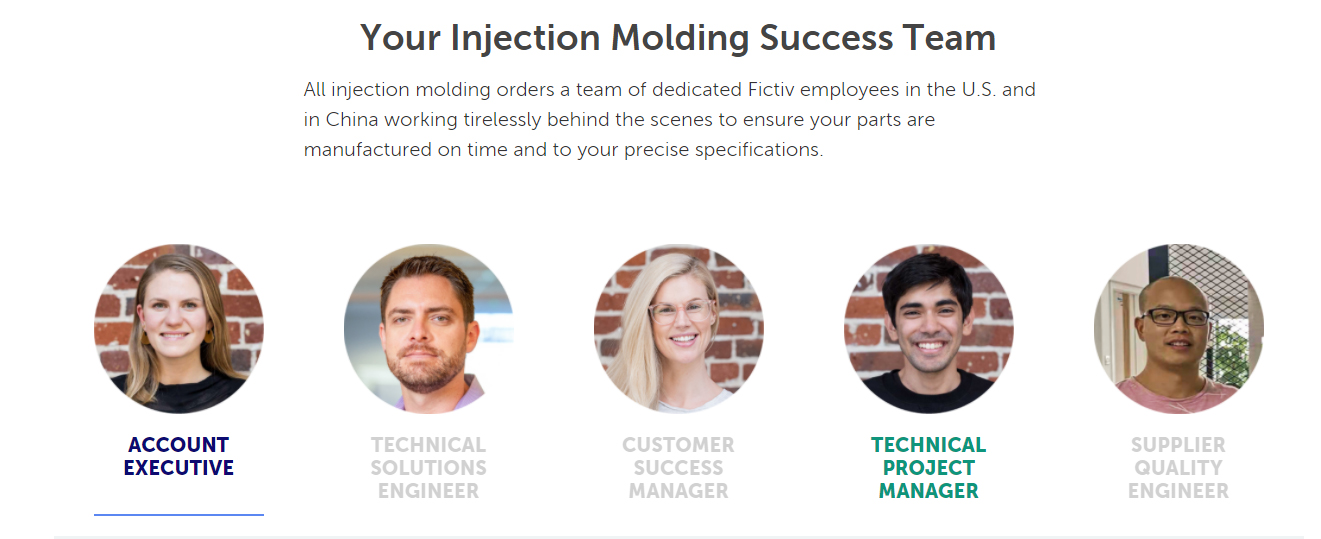

Idea yang bernas dan reka bentuk industri profesional.

Kejuruteraan mekanikal, kejuruteraan elektrik dan DFM komprehensif.

Prototaip pantas dengan bahan dan proses yang betul dan Ekonomis.

Pembuatan yang boleh dipercayai dari bahagian-bahagian untuk melengkapkan binaan kotak.

Perkhidmatan Binaan Kotak FCE

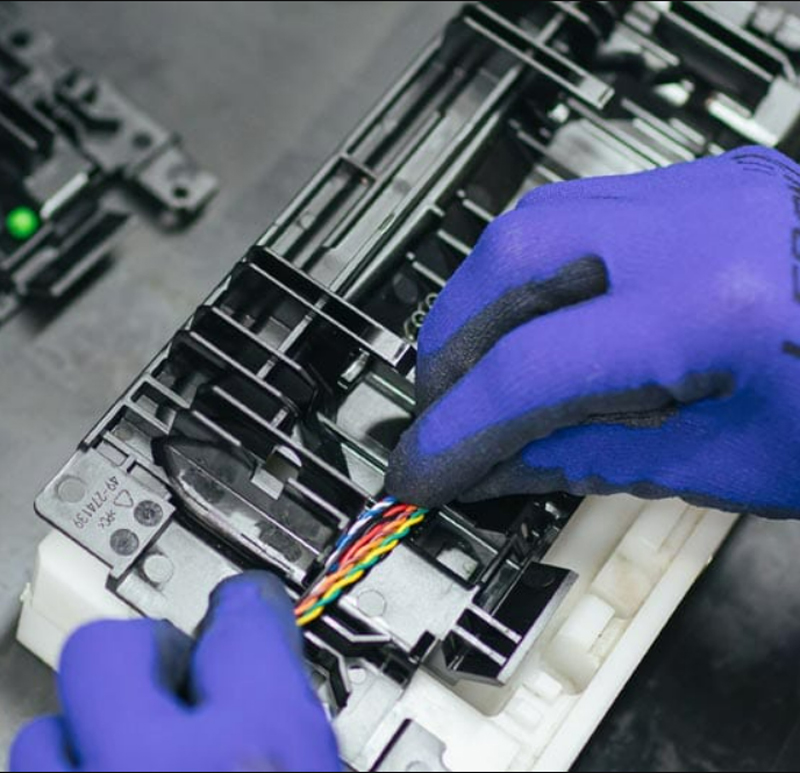

Di FCE, Kami menyampaikan perkhidmatan hujung ke hujung satu stesen, dengan sumber untuk mengendalikan projek berskala besar, digabungkan dengan fleksibiliti dan perhatian terhadap butiran.

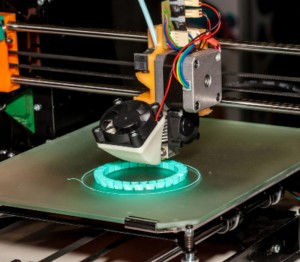

- Pengacuan suntikan, pemesinan, kepingan logam dan bahagian getah dalam pengeluaran rumah

- Pemasangan papan litar bercetak

- Perhimpunan Produk

- Perhimpunan Peringkat Sistem

- Pengujian ICT (In-Circuit Test), Fungsional, Akhir, Alam Sekitar dan Burn-In

- Pemuatan Perisian dan Konfigurasi Produk

- Penyimpanan & Pemenuhan Pesanan & Kebolehkesanan

- Pembungkusan & Pelabelan termasuk Pengekodan Bar

- Perkhidmatan Selepas Pasaran

Gambaran Keseluruhan Kemudahan Pembuatan Kontrak

Di FCE, pengacuan suntikan dalaman, pemesinan tersuai, fabrikasi logam kepingan dan pembuatan PCBA memastikan pembangunan projek yang cepat, berjaya dan menjimatkan kos. Sumber bersepadu membantu mendapatkan semua sokongan tersuai daripada satu tetingkap kenalan.

Bengkel pengacuan suntikan

Bengkel pemesinan

Bengkel kepingan logam

Barisan pengeluaran SMT

Barisan pemasangan sistem

Pembungkusan & Pergudangan

Soalan Lazim Umum

Apakah Perhimpunan Binaan Kotak?

Perhimpunan Binaan Kotak juga dikenali sebagai Integrasi Sistem. Kerja pemasangan yang terlibat dalam proses pemasangan elektromekanikal, yang termasuk pembuatan kepungan, pemasangan PCBA, sub-pemasangan dan pemasangan komponen, pengkabelan dan pemasangan abah-abah wayar. FCE Box Build menawarkan penyelesaian produk daripada pengeluaran bahagian yang boleh dipercayai dan mampu milik kepada pengurusan program menyeluruh dari hujung ke hujung. Sama ada anda perlu membuat satu bahagian atau produk kemasan lengkap dalam pembungkusan runcit, kami mempunyai penyelesaian anda

info apa. Adakah diperlukan untuk sebut harga pembuatan kontrak?

(a) Dimensi produk

(b) Bil Bahan

(c) Model Cad 3D

(d) Kuantiti yang diperlukan

(e) Pembungkusan diperlukan

(f) Alamat Penghantaran

Adakah anda menyediakan perkhidmatan ODM?

Pusat reka bentuk FCE dan firma reka bentuk sumber luar yang bekerjasama boleh menyelesaikan kebanyakan produk perubatan, perindustrian dan pengguna. Setiap kali anda mendapat idea, hubungi kami untuk mengetahui sama ada kami boleh menyokong anda merealisasikan pemikiran anda. FCE akan menyesuaikan reka bentuk dan asas pengeluaran mengikut bajet anda.

Bahan Tersedia untuk fabrikasi logam kepingan

FCE menyediakan 1000+ bahan lembaran biasa dalam stok untuk pemulihan terpantas, Kejuruteraan mekanikal kami akan membantu anda dalam pemilihan bahan, analisis mekanikal, pengoptimuman kebolehlaksanaan

| aluminium | Tembaga | Gangsa | Keluli |

| Aluminium 5052 | Tembaga 101 | Gangsa 220 | Keluli Tahan Karat 301 |

| Aluminium 6061 | Tembaga 260 (Loyang) | Gangsa 510 | Keluli Tahan Karat 304 |

| Kuprum C110 | Keluli Tahan Karat 316/316L | ||

| Keluli, Karbon Rendah |

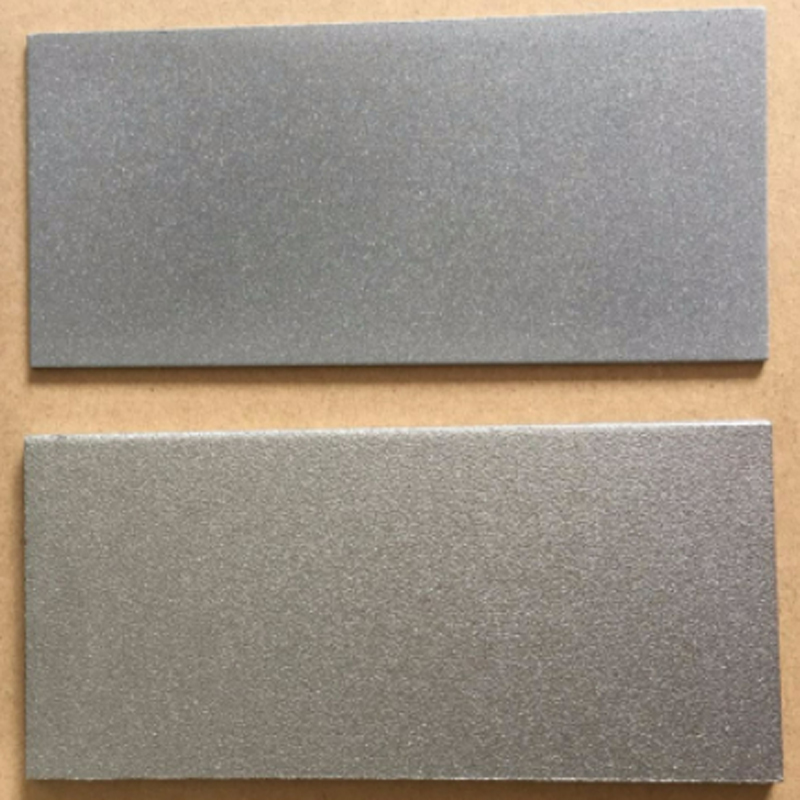

Kemasan Permukaan

FCE menawarkan rangkaian lengkap proses rawatan permukaan. Electroplating, salutan serbuk, anodizing boleh disesuaikan mengikut warna, tekstur dan kecerahan. Kemasan yang sesuai juga boleh disyorkan mengikut keperluan fungsian.

Memberus gigi

Letupan

Menggilap

Anodizing

Salutan Serbuk

Pemindahan Panas

Penyaduran

Percetakan & Tanda Laser

Janji Kualiti Kami